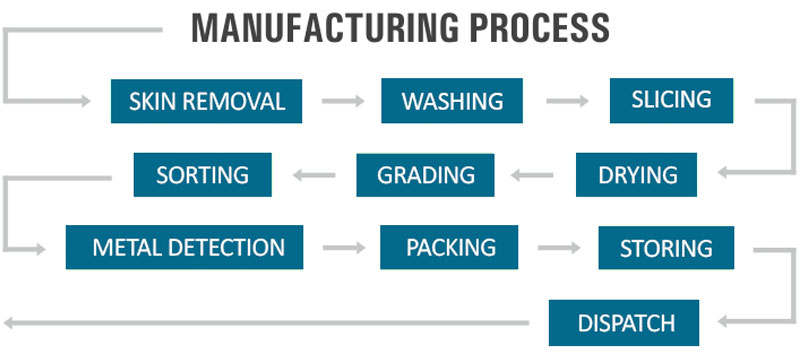

“Where Quality Matters The Most” is our motto. Quality begins from the procurement of raw material from the farms. Our experts will visit the farm and to test the harvest through all the possible and biological methods. The tests are conducted by the expert laboratory technicians with most modern laboratory equipment. This long stage of selection is reflected in the taste and flavour of the final product for quality assurance. The collected raw material is turned into dehydrated products after many steps of production.

Each stage of production includes a quality check. The quality check is performed in our in-house laboratories and we also promote periodic test on certified government laboratories to ensure the compliance of our machinery and production unit. The laboratory equipment is constantly calibrated to give the best test result.

The tested and certified food products go into the next crucial section of our factory, it is the packing section. Products are neatly packed in the high-grade air tight poly bags. This ensures the freshness of the product. All the process is fully mechanized at Krishna Foods and we perform hand free production to ensure the purity and quality of the product.

We are practicing standard quality benchmark with motive to follow strict guidelines under different procedure, likewise:

Packing is the most effective method which protects against barriers of Moisture, Light, Air and Impurities.So, we are selectively deciding food grade packing material for its long-lasting use to keep product safe and hygienic.

Standard Packing and Customize Packaging